Hydraulic filter for XCMG 6720/YX1113/SF-6720/P550388/HF6720

| Part Number | 6720/YX1113/SF-6720/P550388/HF6720 |

| Material | HV paper or Ahlstrom paper or glassfiber or high efficiency China paper. |

| Type | Hydraulic filter |

| Application | Used For XCMG |

| Size And Thread | φ127*170:1.1/2-16 |

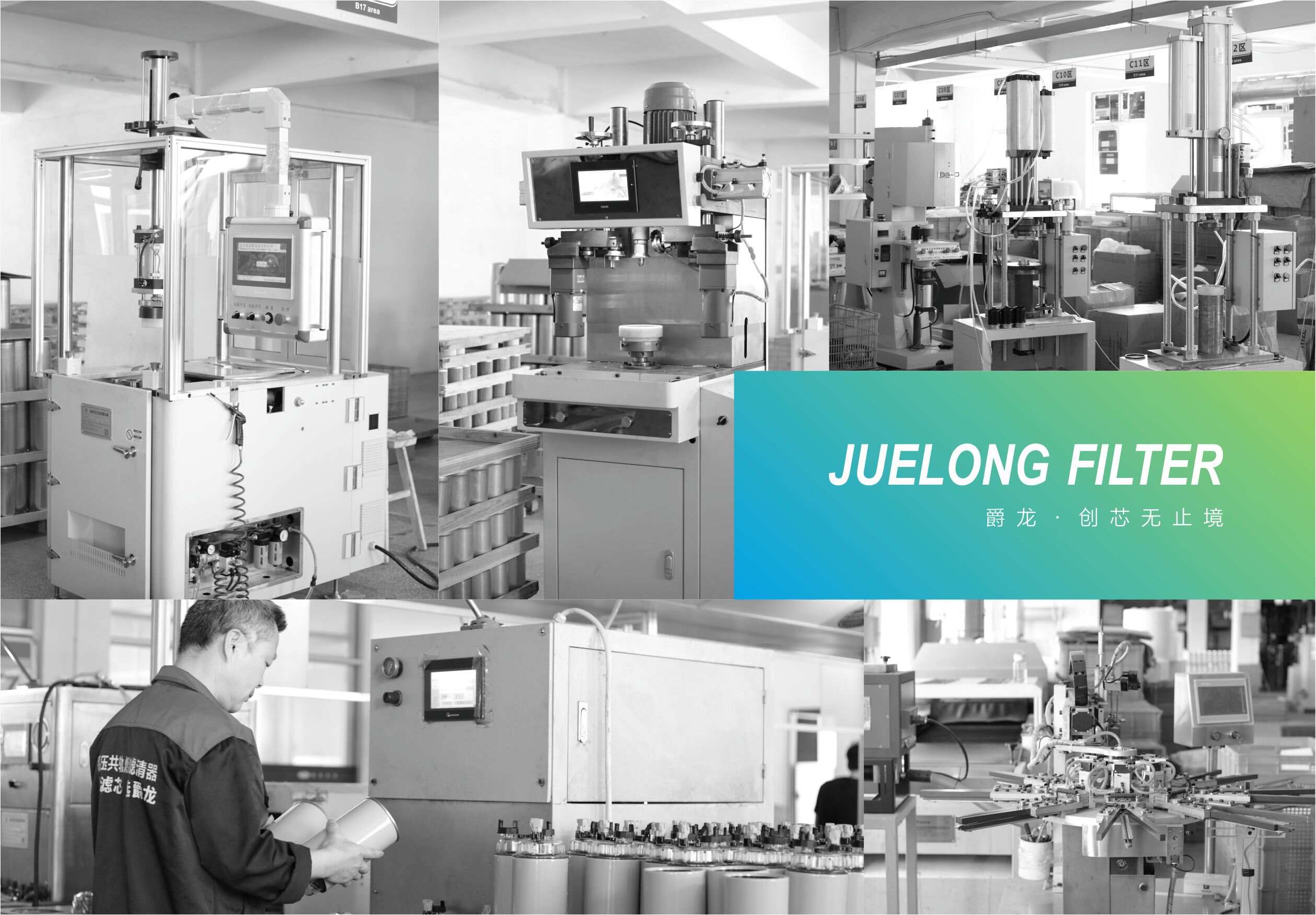

| Package | Juelong® packing or customers' brand packing |

| MOQ | 300-500pcs |

| Guaranteed | 1 year |

FAQ

Q1. What are your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. How about your delivery time?

A: Generally, it will take 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business a long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

What are the requirements for the use of hydraulic filters in hydraulic accessories?

We use a lot of hydraulic filters in hydraulic accessories, including high-pressure filters, oil suction filters, oil return filters, and so on. There are about 6 requirements:

- Reasonably determine the efficiency of filters at all levels. The key points for determining the efficiency of filters are: the performance requirements of final filters, the efficiency specifications of pre-filters should be reasonable, and the maintenance of primary filters and precision filters should be convenient.

- Increase the filter area. The filter has a large filter area, can contain more dust, and has a long service life. Moreover, the filtering area is large, the speed of airflow through the material is low, and the resistance of the filter is small.

- Adjust the efficiency of filters at all levels. The filtration efficiency of the pre-filter is low. You can block the dust in the pre-filter by adjusting the filtration efficiency of the pre-filter.

- The additional effect of the filter should not be emphasized.

- Climatic factors affect the filtering effect. If the filter is used in a large number of willows, corresponding measures should be taken in the air conditioning design, such as changing the height of the air inlet or adding a protective net at the air inlet. If the measures are improper, there is only one move left: change the filter frequently in the floating season.

- The cleaning technology is difficult to popularize the filter with high efficiency, and the use occasions are very particular. Even if the filter cannot be washed badly, it is best not to wash it, unless you are sure to clean it thoroughly and the performance will not change after cleaning.

Structure of hydraulic filter

The general hydraulic filter is mainly composed of a filter element (or filter screen) and shell (or framework). The oil flow area is composed of countless tiny gaps or holes in the filter element. Therefore, when the size of impurities mixed into the oil is larger than these tiny gaps or holes, they are blocked and filtered out from the oil. Because different hydraulic systems have different requirements, it is impossible and sometimes unnecessary to completely filter the impurities mixed into the oil.

The function of hydraulic filter

The hydraulic filter is used to filter various impurities in the hydraulic system. The main sources are mechanical impurities remaining in the hydraulic system after cleaning, such as water rust, casting sand, welding slag, iron filings, coatings, paint skin, and cotton yarn filings, and impurities entering the hydraulic system from the outside, such as dust entering through the oil filler and dust ring; Impurities generated in the working process, such as fragments formed by the hydraulic action of the seal, metal powder generated by relative wear due to movement, colloid, asphaltene and carbon slag produced by oxidation and deterioration of the oil, etc.

Application of hydraulic filters in the industry

Hydraulic filters used in cleanrooms in the industry require continuous and effective removal of smaller particles. The high-efficiency air filter was once the most efficient, and now ultra-low air leakage filter is the most efficient filter. In the future, a new generation of more efficient filters will also be developed and applied. Micro glass fiber filter media is the main choice of filter media, but membrane and electrostatic enhancement media have penetrated this field and obtained some applications.