Hydraulic filter for New Holland 84257511

| Part Number | 84257511 |

| Material | HV paper or Ahlstrom paper or glass fiber or high-efficiency China paper. |

| Type | Hydraulic filter |

| Application | Used For New Holland |

| Size And Thread | φ134*75:1.3/4-16 |

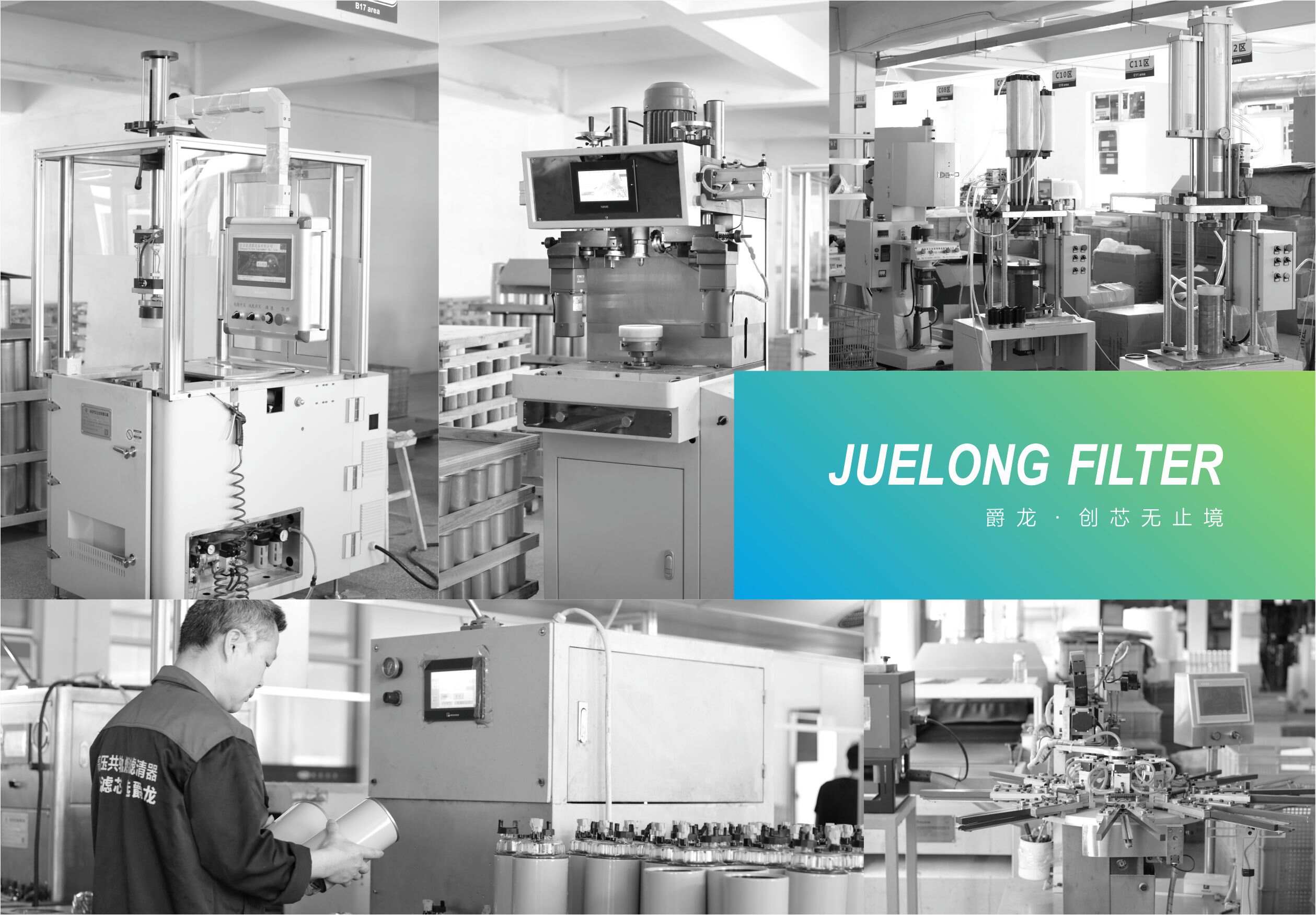

| Package | Juelong® packing or customers' brand packing |

| MOQ | 300-500pcs |

| Guaranteed | 1 year |

FAQ

Q1. What are your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. How about your delivery time?

A: Generally, it will take 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business a long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

kubota svl75 hydraulic filter,bobcat 853 hydraulic filter,kubota m8030 hydraulic filter

The use performance of the hydraulic filter is different, and its filtering mechanism has its characteristics. How to select the hydraulic filter in the hydraulic system? What problems should we pay attention to in the process of selecting the hydraulic filter of the hydraulic system?

Terms, symbols, and definitions

Filtration accuracy: refers to the maximum diameter of spherical pollutants that can pass through the filter element when the oil passes through the filter, in microns( μ m) Indicates.

Maximum flow of filter: the maximum flow through the tested filter at the specified kinematic viscosity recommended by the manufacturer, expressed in L / min.

Pollutant carrying capacity: refers to the weight of pollutants contained in the filter element when the pressure drop of the filter reaches the limit value, expressed in kg.

Filter ratio: the upstream of the filter is greater than or equal to a given size χ The ratio between the number of particulate pollutants downstream and the number of particulate pollutants is greater than or equal to the same given size, using βχ express.

Selection steps of hydraulic filter

Specify the design requirements: specify the hydraulic system pressure, flow, hydraulic oil brand, working temperature, and oil accuracy grade required by the system;

Determine the filtering accuracy level required by the system;

Determine the type of filter according to the installation position and service pressure of the filter in the hydraulic circuit;

Determine the size of specifications: first, pre-select according to experience or preselected nomogram, and then calculate and calculate the initial pressure drop. If it is greater than the above-recommended value, reselect the filter with a larger flow specification;

Determine the pollution transmission mode and bypass the hydraulic filter.

Precautions for hydraulic filter

- The hydraulic filter cannot be filled with oil in the reverse direction, and reliable measures shall be formulated to ensure that workers will not be connected wrongly.

- After the filter element is polluted, the differential pressure flowing through the filter may open the bypass valve, resulting in incomplete oil flow filtration and even crushing the filter screen. Therefore, the filter must be set with a visual or electrical alarm to provide an accurate and reliable indication of whether the filter element needs to be replaced. For the filter whose installation position is not convenient for the operator to observe, the electric signal alarm mode is preferred.

- Hydraulic filter with cold start valve is recommended.

- As the filter element is a vulnerable part, the replacement space of the filter element during maintenance and replacement shall be reserved in the design.

- The steel filter element can be reused, but considering that the cleanliness of the cleaned filter element is difficult to meet the standard, it is recommended to choose a disposable paper filter element.

- For the system with a single-piston rod hydraulic cylinder, pay attention to the difference in return oil flow when the piston is extended and retracted: the ratio of return oil without rod cavity during internal contraction to that with rod cavity during extension is equal to the ratio of the effective working area of the two cavities.

- For the system with oil suction and return filter, the oil return flow shall be 20% higher than the oil suction flow to avoid instantaneous insufficient oil return. The system directly sucks oil from the oil tank without filtering.