Hydraulic filter for LONGKING RP21-51A21000A0

| Part Number | RP21-51A21000A0 |

| Material | HV paper or Ahlstrom paper or glass fiber or high-efficiency China paper. |

| Type | Hydraulic filter |

| Application | Used For LONGKING |

| Size And Thread | φ125*230:1.1/4GAS |

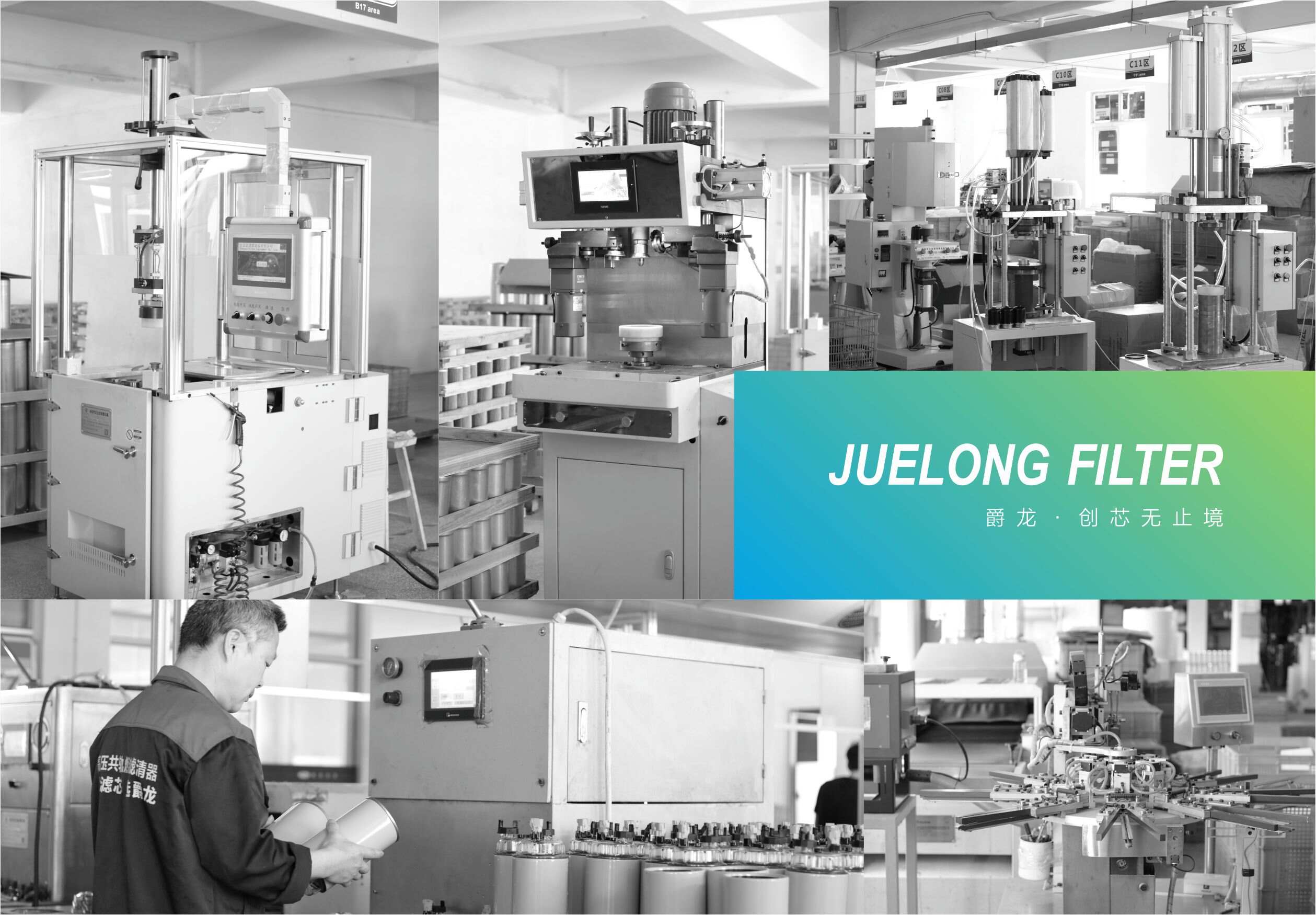

| Package | Juelong® packing or customers' brand packing |

| MOQ | 300-500pcs |

| Guaranteed | 1 year |

FAQ

Q1. What are your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. How about your delivery time?

A: Generally, it will take 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business a long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Five knowledge points that must be known for the correct selection of hydraulic filter

A proper filter system is an essential condition for the long-life operation of the hydraulic system, but choosing the right filter is often not an easy task.

In different industries, different components of the hydraulic system have their requirements and interact with each other. Finally, it involves how to select the seemingly simple filter element. To avoid the high cost of system operation, when selecting filter elements, you need to consider not only the requirements of pressure, flow, and cleanliness, but also an overview of the applied working conditions. This paper lists five knowledge points that must be mastered when calculating and selecting filters.

- Familiar with application conditions

The first and most important thing is to understand the performance requirements of the filter. When accurately calculating the filter specification, the performance requirements usually use the filter ratio β Value, the so-called β Value refers to the ratio of the number of particles larger than a certain size in the fluid at the inlet of the filter to the number of particles larger than a certain size in the fluid at the outlet of the filter. therefore β The higher the value, the higher the filtering efficiency of the filter. β The value can also be expressed as a percentage to indicate its efficiency, η= 1-1/ β.

- Hydraulic system

Once you have established the specific performance requirements for the application conditions, you can correctly evaluate the hydraulic system. According to industry standards, the hydraulic components installed in the hydraulic circuit directly affect the type of hydraulic filter. Such an industry-standard is mainly the ISO cleanliness grade code, which helps us select the appropriate filter type. For example, the proportional valve circuit requires at least 20 / 18 / 15 ISO cleanliness level requirements. To meet this, the absolute filtering accuracy of the filter element shall be at least 3 or 6 μ M.

If only the gear pump and directional valve are included in the circuit, they are relatively insensitive to pollution. Therefore, the filter with low-performance characteristics can meet its requirements - such as paper or metal mesh filter element may be an economic choice. Knowing what kind of hydraulic components are suitable for what kind of filter and understanding how they affect the performance of the filter can save some unnecessary costs for long-term operation.

- Understand the oil viscosity

When selecting the filter element specification, one often overlooked fact is the oil viscosity. Viscosity has a great influence on the selection of filter element specifications. In the initial selection of filter element specification, the oil viscosity is often ignored. The operating cost is too high, which leads to the unnecessary selection of filter elements. Failure to understand the importance of oil viscosity may lead to too small filter element specification, too high-pressure drop, premature alarm of pollution transmitter, etc.

On the contrary, it is also possible that the filter element specification is too large, resulting in too high investment cost and operation and replacement cost. Users need to clearly understand the hydraulic system and evaluate it's rated working temperature range so that the most accurate minimum temperature can be used as the basis for the selection of filter element specifications. Proper selection of the working temperature range can ensure that the filter element will not enter the bypass mode in advance and avoid excessive selection of the filter element.

- About pollution transmitting device

Assuming that the filter is equipped with a pollution transmitting device (analog or digital) when selecting the filter, the user should have an appropriate target requirement for its pressure drop. Generally, the pressure difference shown by the transmitting device ranges from 1 to 8 bar. As a general principle, the ratio of the set pressure of the transmitting device to the pressure drop of the clean filter is at least 3:1.

- Check the flow through the filter

When selecting a filter, you must carefully analyze the flow, which is very important. It should be noted that the instantaneous flow may exceed the maximum flow of the pump. The typical working condition is that in an accumulator circuit, the accumulator stores a certain amount of pressure oil. When the accumulator is released, the discharge flow will be superimposed on the pump flow, which greatly exceeds the discharge flow of the pump itself.

The high-pressure filter after the accumulator circuit must take this into full consideration. Underestimating the flow through the filter will increase the differential pressure of the filter element, which will eventually reduce the loop efficiency and increase the operation and maintenance costs.