Best Price Replacement Ingersoll Rand Oil filter 24900458 for Ingersoll Rand Air Compressor Filter

- Installation locationPressure storage tank

- Residual oil rate1-3mg/m3

- Initial pressure difference0.17-0.2bar

- Limited Data0.5-80m3/min

| Part Number | 24900458 |

| Material | HV paper or Ahlstrom paper or glassfiber or high efficiency China paper. |

| Type | Hydraulic filter |

| Application | Used For Ingersoll Rand |

| Size And Thread | φ119.38*360 : 1 3/4-12 |

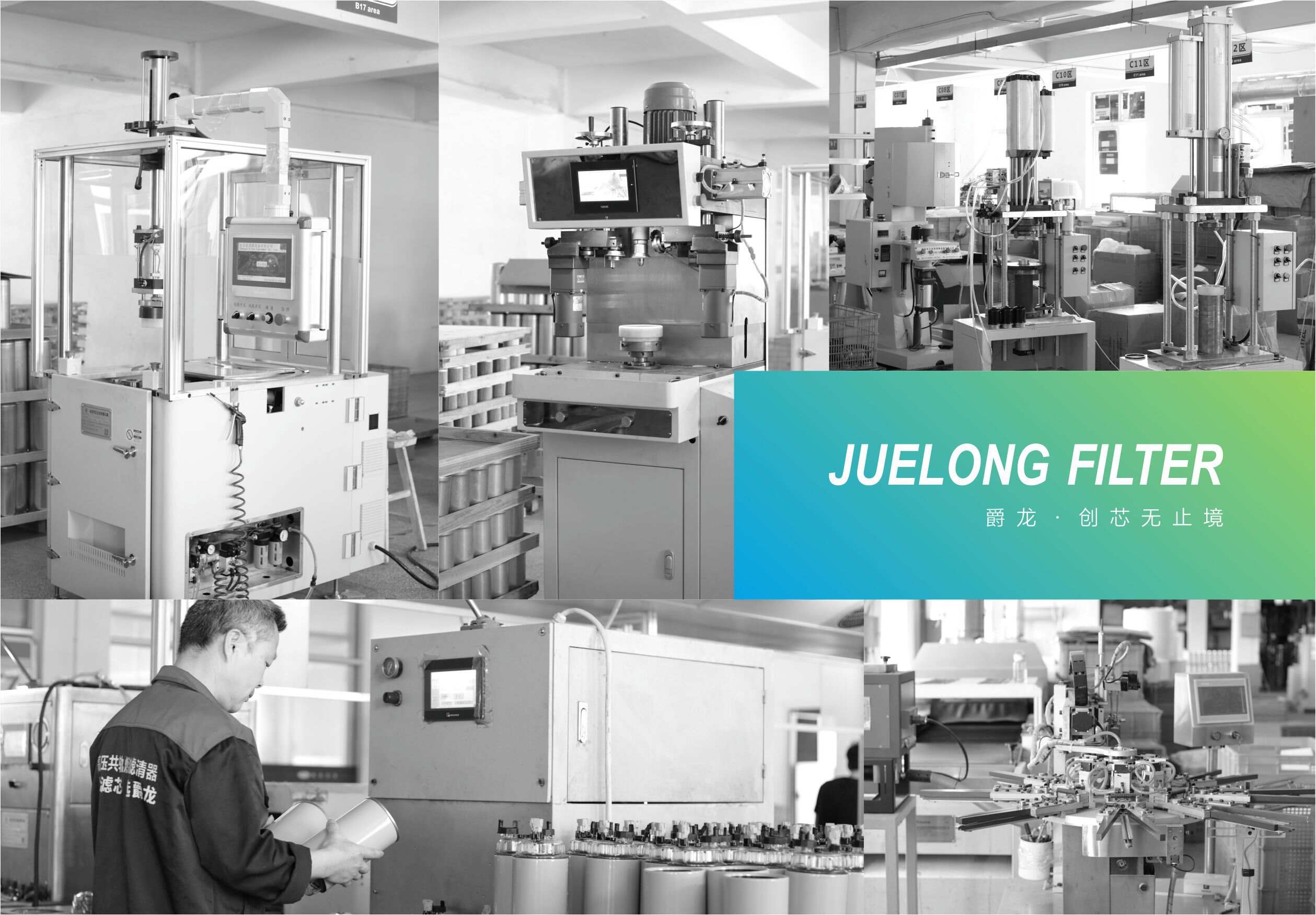

| Package | Juelong® packing or customers' brand packing |

| MOQ | 300-500pcs |

| Guaranteed | 1 year |

FAQ

Q1. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. How about your delivery time?

A: Generally, it will take 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

What Does an Air Compressor Filter Do?

Air compressor filters, also called air line filters, are used in condensed air lines as a way to stop liquids and solid contaminants from entering air compressors. They stop these contaminants from entering the equipment and causing damage. A cubic foot of compressed air may harbor millions of dirt particles, in addition to significant amounts of oil and water. Depending on the application, the compressed air might even contain lead, mercury or other heavy metals.

Without air compressor filters removing such contaminants, the operation of critical system components, such as cylinders and valves, will be compromised. Air filtration is an essential element of proper compressed air preparation and can also prevent seals from swelling and experiencing premature wear. In addition to reducing downtime, clean compressed air results in lower energy costs.

How Does an Air Compressor Filter Work?

Air line filters work by straining air to trap solid particles and separate liquids from compressed air. To clarify the process, it helps to identify the main components found in an air compressor filter:

- Inlet: The air compressor intake or inlet is where air enters the filter. There is an internal cap that forces air downward into a spiral. It’s important to get the right size inlet rather than using a filter smaller than the line.

- Filter cap: This component directs airflow through the filter. You can tell the direction of the air by the arrow on the outside of the filter, which also prevents you from installing it backward.

- Air path:This is the actual path the air follows as it spins like a cyclone and passes through the air filter itself.

- Filter discharge:This orifice allows air to leave the filter, and it should match the inlet size. If the filter discharge is too small, it will restrict the flow of air.

- Filter element:The filter itself is what takes contaminants out of the air, catching particulates over time. Eventually, filters become clogged and must be cleaned or replaced.

- Filter bowl:The bowl is the biggest part of the filter that you can see. It is connected to the cap and is threaded or twisted and locked into place.

- Filter quiet zone:The contaminants, water and oil collected by the filter all end up in the quiet zone at the bottom of the filter. You will usually find a barrier hanging from the filter bottom, preventing debris from being reintroduced into the air.

- Drain:Collected contaminants and debris have to be drained. Many filters must be drained manually, but others have float-operated or electric auto drains.

In the first stage of filtration, compressed air passes through a mesh filter. This creates a clumping effect where the larger particles are trapped by the filter, and the water condenses into bigger droplets then travels to the separation chamber.

The compressed air slows down, allowing particulates to condense on a pad with honeycomb-like qualities. This facilitates the movement of droplets to the drain. After entering the drainage system, droplets are discharged through the drain valve. This stage of filtration removes a majority of the oil, large particles and water droplets.

Micron Measures

Air compressor filters catch particles so small that they are measured in microns. One micron is one-millionth of a meter. For scale, the width of a human hair is usually at least 70 microns. Fine particulate filters can remove particles as small as five microns, while a general-purpose filter will catch particles down to 30 or 40 microns in size.

When using a fine particulate filter, the risk of immediate clogging is significant. To keep air flowing while still capturing minuscule particles, it’s a good idea to use a fine particulate filter in tandem with a general-purpose filter up-stream. That way, larger particles are caught before they can clog the finer filter.

We have High Quality Deutz Excavator Hydraulic Filter For Forklift for sale, for more information, we are glad to serve you.