Fuel/Water Separator Filter for JCB 320/07483

| Part Number | 320/07483 |

| Material | HV paper or Ahlstrom paper or glassfiber or high efficiency China paper. |

| Type | Fuel/Water Separator Filter |

| Application | Used For JCB |

| Size And Thread | φ111.3*261 |

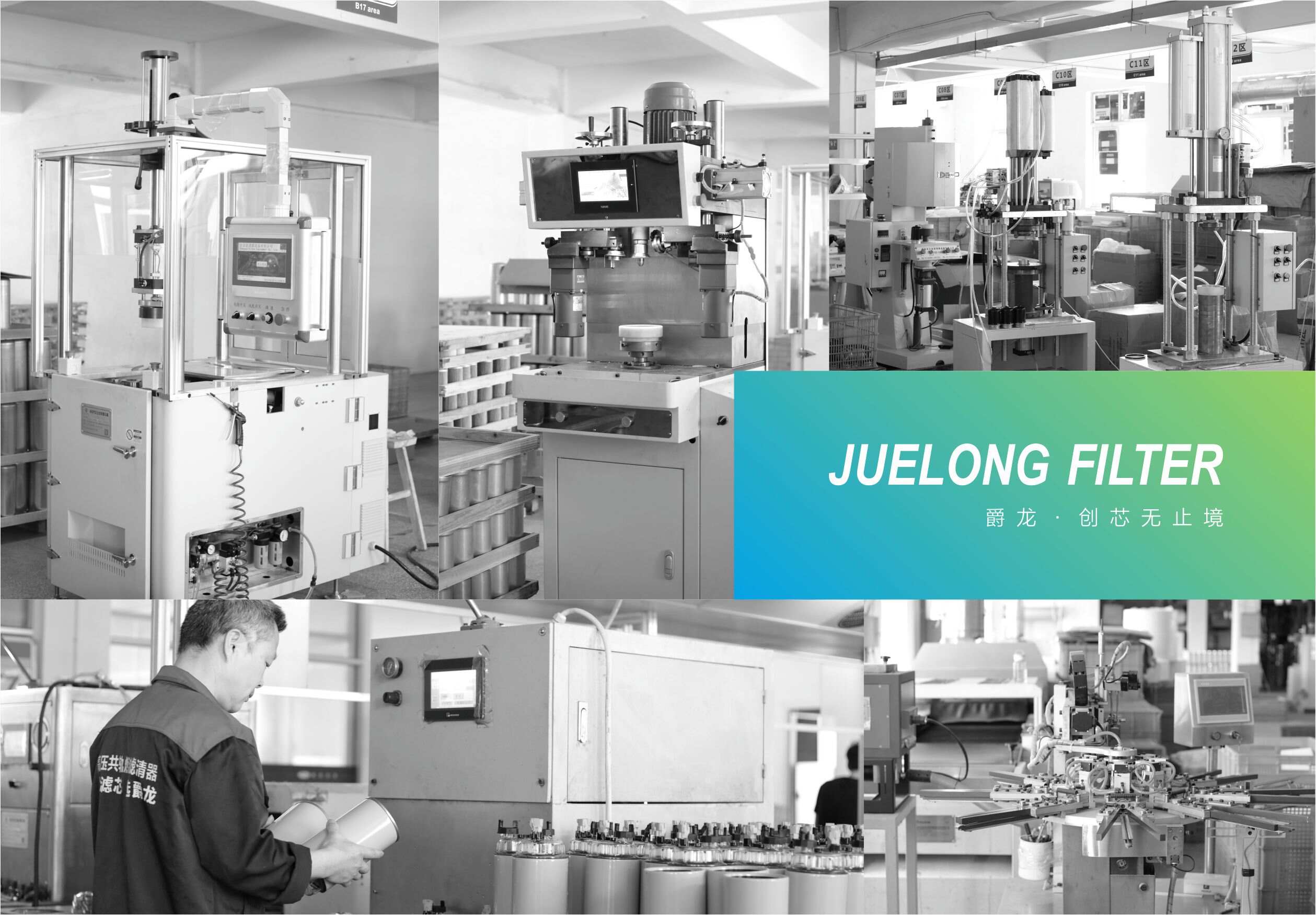

| Package | Juelong® packing or customers' brand packing |

| MOQ | 300-500pcs |

| Guaranteed | 1 year |

FAQ

Q1. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. How about your delivery time?

A: Generally, it will take 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

cat water separator filter,cat fuel water separator,oil separator volvo d13

5 Top Tips For Choosing a Fuel Water Separator

✔️The Filter Element

A fuel filter is an in-line device for any engine using fuel, be it gasoline or diesel.

There are different filters for different applications. When fuel passes through the filter media, the filter “catches” dirt particles. The size of the pores in the filter determines the size of the particles that it captures. We call this “micron level” and is available in 2, 10, or 30 microns, indicating the size of the particles it will catch. Most marine and industrial systems utilize a 10- and 30-micron filters between the fuel tank and the engine.

For sensitive performance systems, a secondary two micron filter can be installed downstream from the primary filter for additional protection.

✔️The Inspection Bowl

It is common to find water in fuel. This is due to many facets like condensation and pollutants found in the fuel. To diminish damage and increase efficiency water and pollutants should be removed from this fuel. We use a separation system to do this.

The fuel water separator uses a pleated filter media. This filter catches water particles and makes them into bigger droplets. These droplets are heavier than the fuel and will then fall into a collection bowl at the bottom of the filter.

The collection bowl comes in many forms. Bowls may be made of clear plastic, aluminum, or a combination of both – a clear bowl with an aluminum heat shield for protection from the hot engines. Filters with clear collection bowls should not be used in an enclosed engine compartment. Often the heat in the engine compartment is very high and the plastic materials are not rated for these temperatures. Collection bowls can be reused several times before they need to be replaced.

All collection bowls have some type of drain plug, which is used to empty the water from the collection bowl. Draining the water from these bowls from time to time is a must. This ensures the proper operation of your filter. Clear bowls are easier to use; as you can see the water level in the bowl to determine the timing of the draining. Metal drain bowls are not as easy to determine when to drain the water. Filters with metal drain bowls should be drained every few days to ensure the proper operation of the filter.

✔️The Fuel Flow Rate

Fuel-flow rate is critically important when selecting a fuel water separator. Always check back with the engine manufacturer for the correct size filter for your fuel water separator.

Typically, the larger the engine, the larger your fuel water separator should be. As a general rule of thumb, the required flow rate of your fuel water separator is about 10 percent of the rating of your engine. So for example, a 200-hp engine would require a 20-gallons-per-hour (GPH) filter. Our CFS1020 diesel separator cleans your fuel at 20 GPH.

The typical formula for average fuel usage at gallons per hour (GPH) is to divide horsepower by 10:

Horsepower (HP) ÷ 10 = Gallons-Per-Hour (GPH)

So a boater with a four-stroke, 250-hp marine outboard engine with a fully open throttle is using 25 GPH.

Consumption is what your engine burns, flow is what has to move through the system; many engines have a system that sends fuel back to the tank. Make sure the water separator you choose has the correct flow specification.

✔️Engine Size

Simply stated, bigger engines need bigger separators. The same goes for smaller engines they need smaller separators.

This is because the flow rates are different. Think of flow as a volume. Smaller separators have lower flow and the opposite for larger separators.

When replacing the separator a quick visual check of the comparative size will give you an early head’s up.

✔️Environmental Applications

Your selection of a fuel water separator should also be based upon the type of environment the filter is expected to perform in. Moderate environmental conditions such as mild climates and moderate usage of these systems may not require fuel water separators. However, in harsher environments it is highly recommended to use a fuel water separator.

In harsher environments such as construction sites or heavily soiled environments, excessive dirt and debris often finds its way into fuel storage systems. In turn, the engines in these environments are subject to this contaminated fuel.

In high humidity environments such as coastal regions, areas with high levels of precipitation, or regions with humidity levels above 50% should use a fuel filter water separator. These environments facilitate the collection of water vapors and droplets in the fuel system, and without the proper removal of these water contaminants, severe engine damage can occur.

We have Fuel/Water Separator Filter for JCB 320/07483 for sale, for more information, we are glad to serve you.